The Reduction of Lead in Drinking Water Act

The “Reduction of Lead in Drinking Water Act” was enacted on January 4, 2011 and signed by President Obama. The purpose of this Act was to amend Section 1417 of the Safe Drinking Water Act (“SDWA” or “the Act”). The Act established a prospective effective date of January 4, 2014, which provided a three-year time frame for affected parties to transition to the new requirements.

Since 1986, the Safe Drinking Water Act has prohibited the use of certain items that are not lead free and since 1996 the Act has made it unlawful for anyone to introduce into commerce items that are not lead free. The primary purpose of the 2011 change was to lower the maximum lead content of the wetted surfaces of plumbing products such as pipes, pipe fittings, plumbing fittings and fixtures from 8.0% to a weighted average of 0.25%. The Act also established a statutory method for the calculation of lead content (now known as Annex G). Finally, to eliminate the requirement that lead free products be in compliance with voluntary standards established in accordance with SDWA 1417(e) for leaching of lead from new plumbing fittings and fixtures. Since the voluntary standard was eliminated, this made it clear to the industry that the lead content requirements would now be mandated, which would require “Third-Party Certification” by a “Nationally Recognized Testing Laboratory”.

NSF 61 – The Standard

Since the Act required a standard be set to determine compliance, NSF 61 was developed to provide a standard for the approval of such products to facilitate compliance. As NSF 61 has been modified over the years, a number of additional clarifications of compliant materials and methods were created. These materials and methods are known as Annex G. At about the same time that Annex G was evolving, California passed a separate State Law known as AB 1953 which required both NSF 61 compliance, as well as a quality standard and revised the lead content down to “lead-free” as defined by the standard. Once the California Law was in place, and with the imminent mandate of January 2014 on the horizon, a trickle-down effect started to occur and consultants, contractors and manufacturers either began the certification process or were well under way. The new method for determining this “lead free” (a weighted average of .025%) mandate has become known as NSF 372.

NSF 372 is Synonymous with CA AB1953

NSF 372 is NOT a standard. It is a method of measurement used to comply with the standard. Therefore, anything that has a full NSF 61 Certification has been certified to NSF 61 via the methods and values defined in NSF 372. Since NSF 372 actually mirrors the California AB1953 Law, it will eventually replace the language. This means that to have a certification by a third-party laboratory which says that your product is in compliance with CA AB1953, you have already complied with the same standards as defined by NSF 372, so the certification is semantics.

QuantumFlo’s Systems are fully NSF 61 and NSF 372 Certified

Contact your local QuantumFlo Authorized Representative to find out more.

Misrepresenting the STANDARD

SDWA Section 1417 was revised to put teeth into the Act from a legal standpoint by:

• Lowering the maximum lead content of the wetted surface of plumbing products such as pipes, fittings, plumbing fittings and fixtures from 8.0% weighted average (1986) to 0.25%.

• Establish a statutory method for the calculation of lead content. (which became NSF 372)

• Eliminate the requirement that lead free products be in compliance with voluntary standards established in accordance with SDWA(e) for leaching of lead from new plumbing fittings and fixtures.

You will notice that the Act which went into effect January 4, 2014 now makes it UNLAWFUL for non-compliance! Since this is a FEDERAL mandate, it is automatically enforced without the need for adoption by any local jurisdiction. This is why it became mandatory that all products be in compliance with NSF 61 in January of 2014. This is also backed by the Uniform Plumbing Code (UPC) and International Plumbing Code (IPC) which recognize and enforce the NSF 61 Standard in their associated codes. Both the IPC and UPC DO NOT recognize NSF 372 as a standard since it is part of the procedure to facilitate certification to NSF 61. You will also note that the SDWA Section 1417 recognizes all plumbing devices, including pipes, fittings and all components within the plumbing system from “source to tap”. In the case of a commercial building, the law is applied to anything in the plumbing system from the water meter to the last fixture in the building.

Boosters are now considered one of these plumbing devices which are pre-fabricated and therefore must be compliant as a complete system. The only way to guarantee that standards are met was to certify the “system” rather than the sum of all parts. This means that the system is now part of a certification program which requires the manufacturer to document the materials of construction and have the “system” tested as a complete device within the plumbing system. Simply using NSF Certified valves, pumps, fittings, tubing, etc. is not sufficient because the system has not passed the NSF 61 Standard in accordance with NSF 372 requirements.

As the deadline has approached and passed, some manufacturers did not begin compliance testing on their products and are now trying to scramble to get testing. Unfortunately, there are now Federal Statutes being violated as these manufacturers have not taken the statue seriously or they feel that enforcement would be lax. The booster system MUST be certified as a complete system with all passageway components assessed and certified to the NSF 61 standard. This is the certification that QuantumFlo holds on all of our products and it is the ONLY reason that label can be affixed to the controller (signifying that the “system” and not the “component” are certified). Additional components within our system will sometimes have additional NSF Labels themselves, but these components are highly regulated by our certification and any change in these components must be documented and re-certified with the laboratory, particularly if their chemical makeup changes. These components include:

1. Coatings

2. Pipes

3. Valves

4. Gaskets

5. Headers

6. Fittings

The NSF 61 and NSF 372 SCAM

Know Your Manufacturer

ENGINEERS, CONTRACTORS and OWNERS, BEWARE! There are manufacturers out there who continue to try to game the system, but their irresponsibility can easily become YOUR LOSS! Here is an excerpt from the EPA in a summary statement made about the SDWA Section 1417.

Since 1986, the Safe Drinking Water Act (“SDWA” or “the Act”) has prohibited the use of certain items that are not lead free and since 1996 the Act has made it unlawful for anyone to introduce into commerce items that are not lead free.

ANY MANUFACTURER WHO IS MISLEADING THEIR CUSTOMERS INTO BELIEVING THAT THEIR SYSTEM IS CERTIFIED TO THE STANDARD IS VIOLATING FEDERAL LAW AS OF JANUARY 4, 2014! There is no nice way to say this! Unfortunately, this irresponsible behavior has become commonplace within the industry as there have been many manufacturers who have put off certification believing the enforcement would be low.

QuantumFlo’s President and CEO, David Carrier, spoke with our third party lab regarding the testing of components and systems and this is what they said:

Manufacturers can request the testing and certification of either a component or a system. If a client chooses to only certify a component, then only the component can be labeled and advertised as certified.

To clarify, standard NSF/ANSI 61 addresses several different types of potential contaminants, but not specifically lead content. Low lead requirements are defined separately in three different requirements:

• Federal lead law: “Reduction of Lead in Drinking Water Act” – Effective January 4, 2014

• California lead law: “The California health & Safety Code 116875”

• NSF/ANSI 372: Standard, not a law, providing test methods.

It is important to note that having compliance to NSF/ANSI 372 does not substitute certification to either the Federal or CA State lead laws.

If a manufacturer has a SYSTEM certification, this will be obvious to the user if they look at the certification document provided by the test laboratory. The QuantumFlo Certification is, without question, perfectly clear. Here is an excerpt from that portion:

QuantumFlo NSF61 Certification

QuantumFlo’s NSF372 Certification

If the certification does NOT show the complete series of product, BE CAREFUL! The manufacturer may have ONLY certified a component and NOT the system. This does NOT make them compliant as a system! As mentioned previously, there are many different components within the system in addition to many different laboratory and chemical tests required by NSF 61 which make up the compliance to the standard. Any product that represents their system as compliant and has not completed system testing is in violation of Federal law.

QuantumFlo’s Systems are fully NSF 61 and NSF 372 Certified

Contact your local QuantumFlo Authorized Representative to find out more.

SUMMARY

QuantumFlo’s Booster Systems Are Fully Certified as NSF 61 and NSF 372 Compliant

When it comes to “booster systems” the law is very clear. Since the SDWA references ANY device within the potable water system, the booster is, by this measure within the potable water system. Here is an excerpt from the EPA, Summary of Lead in Drinking Water Act and Frequently Asked Questions;

EPA interprets “potable services” to be services or applications that provide water suitable for human ingestion (e.g. drinking, teeth brushing, food preparation, dishwashing, maintaining oral hygiene).

There is only one solution for a device which was installed in the potable water system that cannot pass compliance; replacement of the entire device. Any item that is/was installed after the January 4, 2014 deadline that does not meet the definition and is not certified accordingly must be removed from the system. In many cases, the manufacturer is not the loser, the OWNER, ENGINEER and CONTRACTOR are. I am certain that this will likely create many new lawsuits that will be fought between these parties as to who is responsible for the violation and subsequently, who will pay for the labor and product cost to completely replace new equipment that does not meet the standard.

The EPA further defines the term “introduction into commerce,” which is the term used in SDWA Section 1417(a)(3).

In 1998, after Section 1417 was amended to prohibit the introduction into commerce of any pipes, pipe or plumbing fittings or fixtures, EPA issued guidance on the enforcement and implementation of Section 1417. In the guidance, EPA explained that it “interprets ‘introduce into commerce’ as used in Section 1417 of SDWA to cover not only the initial offering of products for sale but also the sale or distribution from an inventory of products.” (WSG #129, Sept. 24, 1998, at 2).

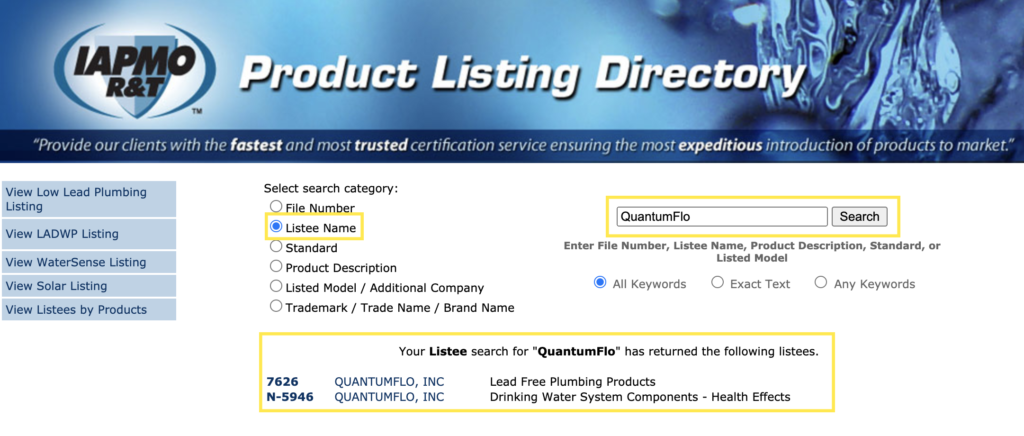

At the end of the day, certification to the standard is about proof. If the manufacturer has not passed product testing in accordance with the procedures set forth in the SDWA and NSF 372, they are NOT APPROVED and are excluded from providing ANY product for potable water service. The danger to all participants is substantial as the engineer specifies and accepts the product, the contractor installs the noncompliant equipment, and the manufacturer and his representative participate in the ruse by misrepresenting the product to all parties. You can verify product compliance for QuantumFlo products by navigating to the IAPMO website, selecting Search by “Listee Name” and typing in “QuantumFlo”.

Contact QuantumFlo

Find out more about QuantumFlo’s advanced variable speed booster solutions.

calQflo® – The World’s Most Intelligent Sizing & Selection Configurator

Calculating for Your Domestic Water or Water Recovery Booster System Has Never Been Easier